Precision Cut-to-length (CTL)

SPPL has state-of-the-art CTL processing plants with a rated capacity of 2,34,000 TPA in HRC, 72,000 TPA in CRC, GP & PPGI, & 40,000 TPA in tin-plates, PCRC & TFS, The facility includes both conventional & modern plants to process in total 3,46,000 TPA in CTL form.

Blanking

SPPL facilitates blanking process in both HR sheets/plates & CR sheet, to create customized bundles as per customer wants & demand. SPPL carries rated capacity to shear or blank 15,000 TPA.

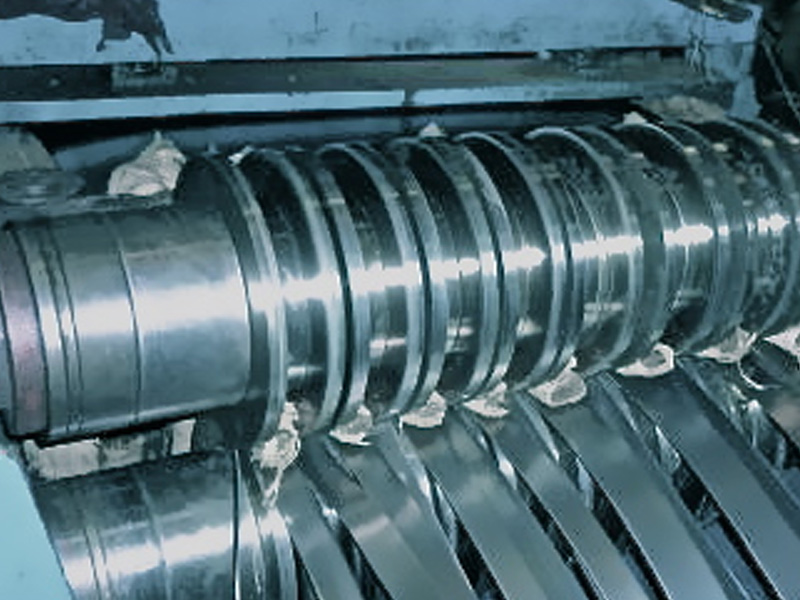

Tin-plates Sheet Slitting & Edge trimming

SPPL carries slitting process of Tin-plates/PCRC/TFS from CTL sheets in to more narrow sheets & stripped sheets. These sheets are processed as per standard dimensions for end-consumer FMCG industry. Edge trimming is a process forming non standard CTL sheets in to primes sheets. Normally, finished tin material lacks quality due to edges being bend or rusted. Therefore these edges are trimmed to create value & quality.

Incorporated in the year 1995, SPPL (Shearline Process Pvt Ltd) started its operations with processing of tin related products & warehousing. Mild steel products such as tin-plates, tin-free, black plates processing & its warehousing is the very first operations carried on during the company laid its foundation.

Shearline Process Pvt Ltd

507, 5th Floor, Bharat Chembers,

Carnac Bunder (East),

Mumbai 400 009.

+91 22 62308097

info@shearlineprocess.com

© All Rights Reserved by Shearline Process Pvt. Ltd.